Maestro's IIoT solutions integrate into Ventsim CONTROL

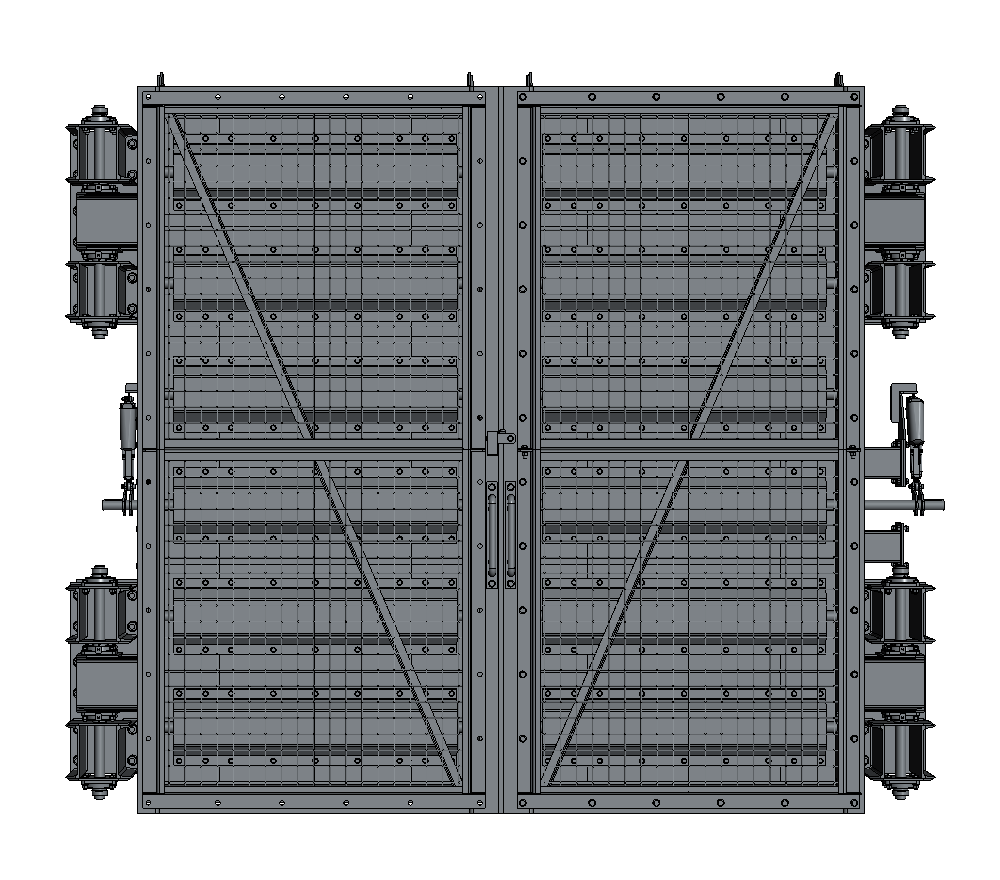

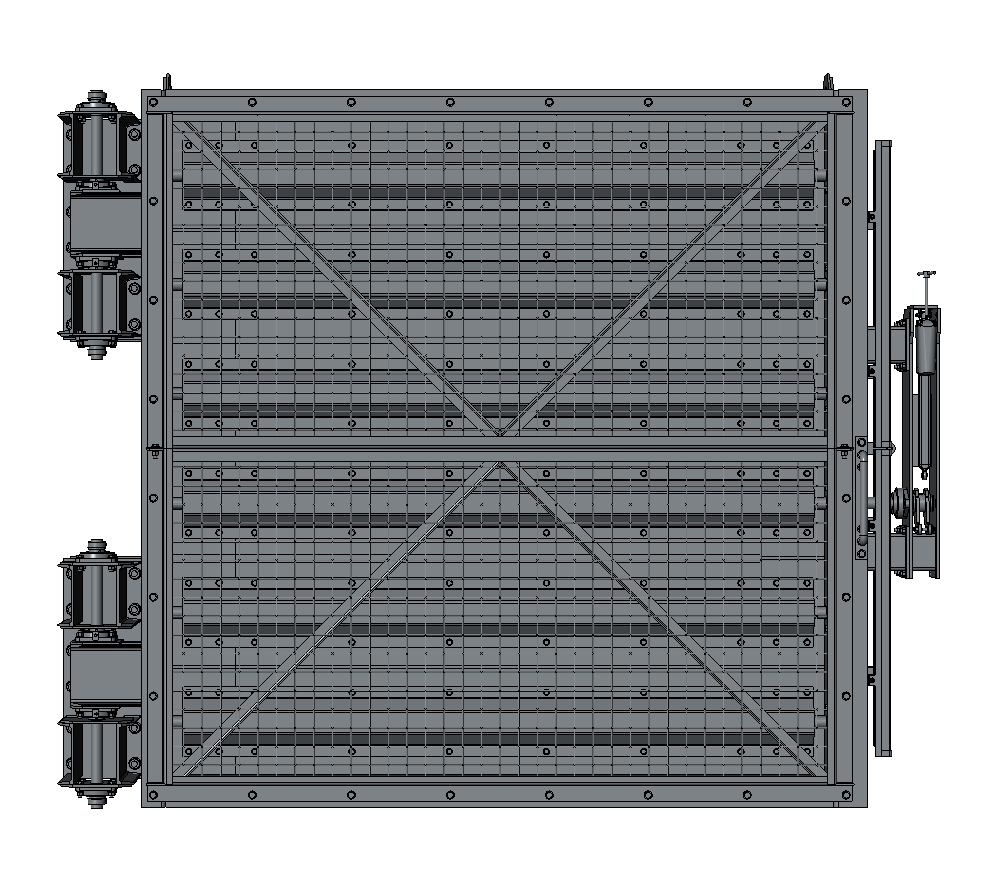

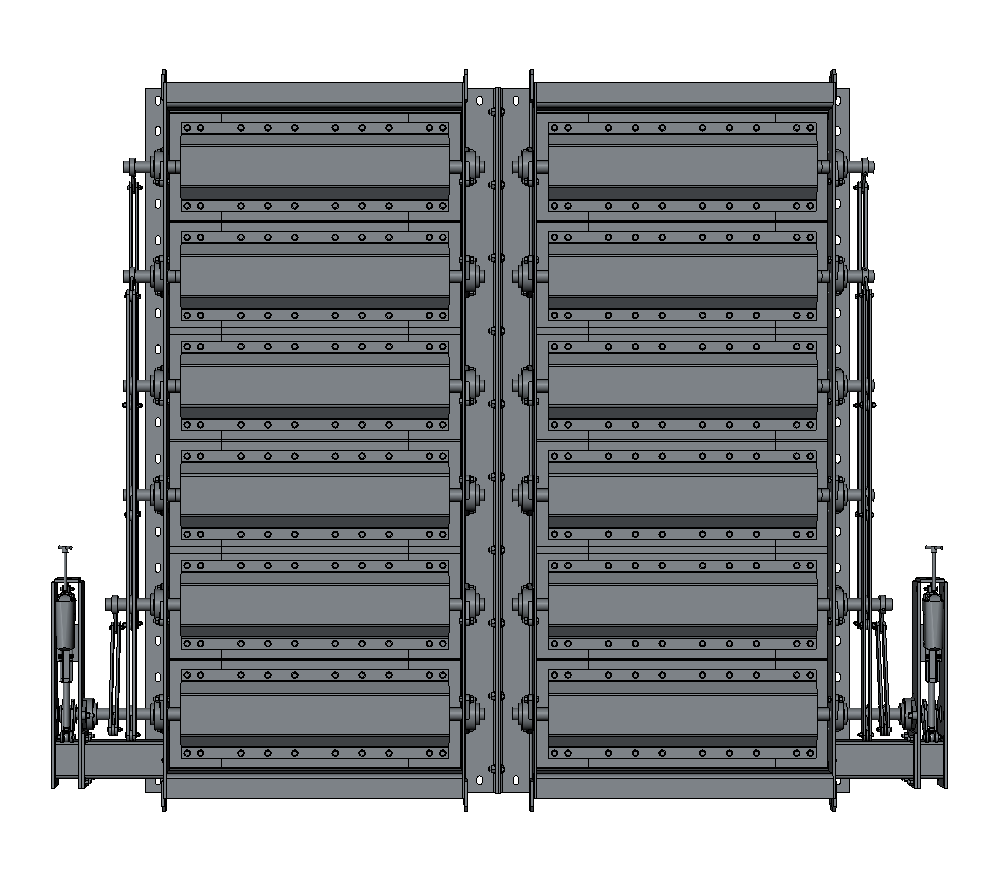

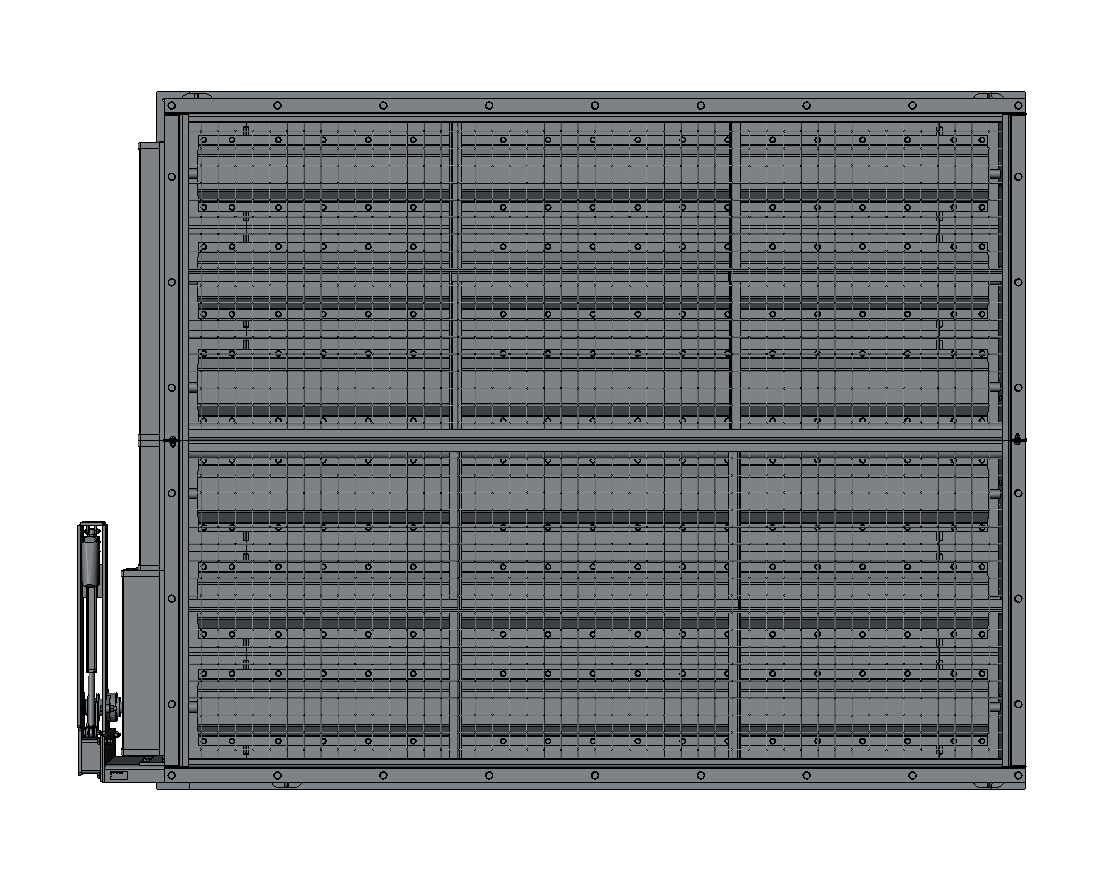

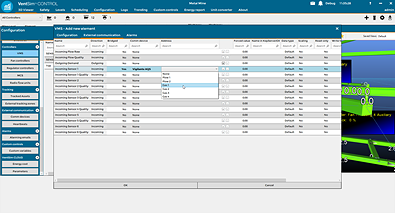

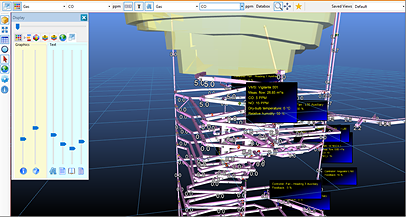

Maestro Digital Mine’s ventilation IIoT solutions have been successfully integrated into Howden's Ventsim CONTROL Ventilation Optimization software, thus strengthening Maestro's mine ventilation solutions for customers around the world. Ventsim CONTROL can remotely monitor, control, and automate in real-time the total underground mine ventilation from the surface. Combined with Maestro's Vigilante AQS™ & Zephyr AQS™ air quality monitoring stations and using MaestroFlex™ automated regulators, Ventsim CONTROL can be easily configured to manage the ventilation by reducing the complexity and integration time of any project.

Ventsim CONTROL uses real-time data to continuously optimize and redirect airflow for peak efficiency and safety in all activity levels and headings in your mine as production priorities shift. Ventsim CONTROL communicates with all hardware and instrumentation mine infrastructure.

“Expanding Ventsim Control’s capabilities to incorporate Maestro’s advanced solutions and plug and play ventilation devices is an exciting and logical next step. The integration will now make it easier than ever for mines to enjoy the safety and security of mine-wide atmospheric monitoring, together with advanced and intelligent ventilation automation to improve safety and productivity and reduce costs. Maestro's core values align with Howden’s in striving for excellence in safety, productivity, and service for our customers,” says Howden’s Craig Stewart – Ventsim Founder.

Maestro developed in partnership with the mining industry an essential and life saving digital technology, the Vigilante AQS™ air quality station, to measure environmental conditions in real-time for worker health and safety and to reduce the total installed infrastructure costs. With the success of the Vigilante AQS™, Maestro went on to develop the Zephyr AQS™ is a low-cost air quality monitoring station for underground mines that now completes internally with the gold standard – Vigilante AQS™ air quality station.

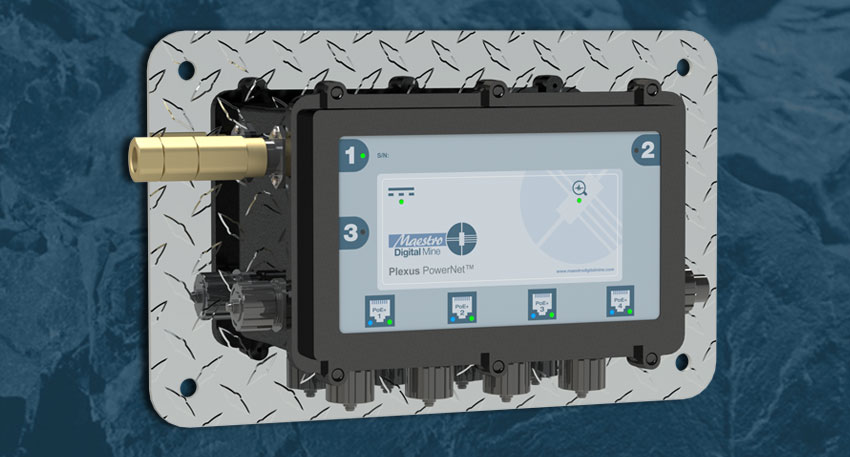

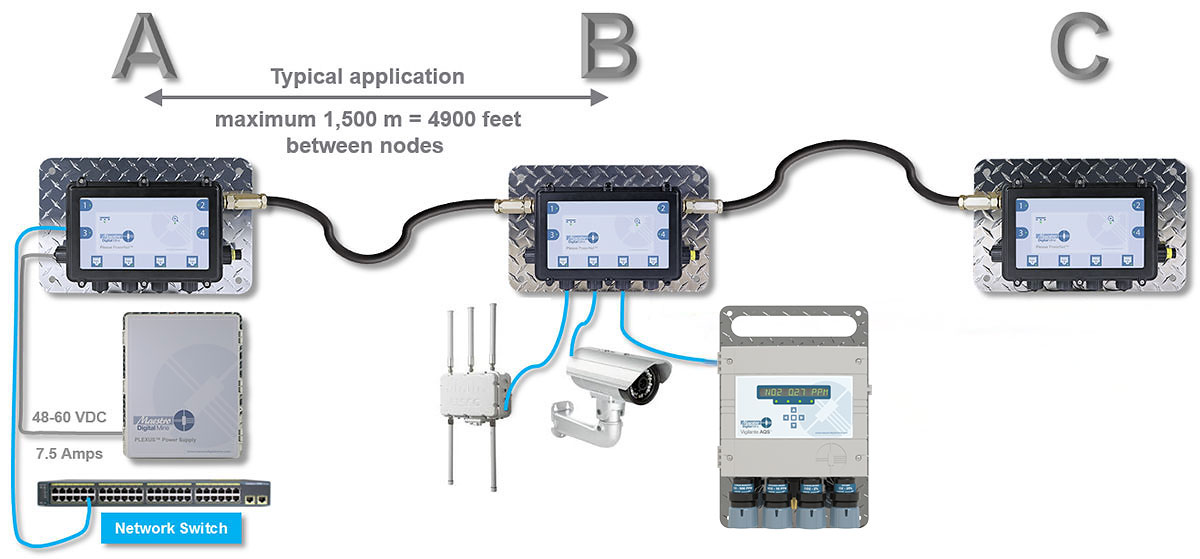

To date, Maestro has thousands of Vigilantes AQS™, hundreds of Zephyrs AQS™ and MaestroFlex™ automated regulators in underground mines and many that are utilizing the Plexus PowerNet™ last mile communication network. MaestroLink™ Server software manages the IIoT devices in the field using advanced edge based diagnostic data thereby reducing on-going calibration and maintenance OPEX. All of Maestro's products are fully digital and have significant information in the form of status bits to determine the health of the sensors and the complete systems. VentSim CONTROL can continue to enhance the customer experience to automate and optimize their mining ventilation to improve mine production, worker safety and significantly reduce a mine's overall energy consumption.

Michael Gribbons, CEO, President and Co-founder, Maestro Digital Mine, stated that, "Maestro is known for its Industrial Internet of Things (IIoT) devices used for ventilation monitoring and controls as well as last mile digital networks for the underground mining sector. These proven solutions installed globally in 35 countries provide safety to the workers, productivity improvements to operators and significant CAPEX and OPEX savings to the project group. Integrating our ventilation solutions into Ventsim CONTROL is one more way we can create a seamless user interface for customers".

https://www.howden.com/en-gb/products/other-products/ventsim-control

About Howden

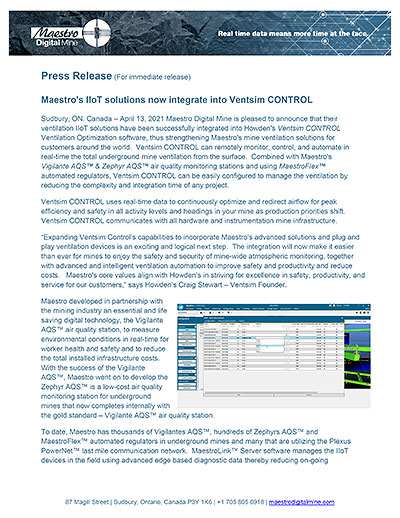

For more than a century, Howden has supplied ventilation fans and equipment to every major mining company in the world. Today, Howden's Total Mine Ventilation Solutions (TMVS) is a fully integrated approach to mine ventilation and air quality control. By reducing blast-clearing downtime, Howden can improve production rates by up to 70%. Howden is able to provide all necessary equipment, services, and Ventsim solutions mine sites require in a fully customizable and integrated product offering: Main and Auxiliary Fans, Mine Heaters, Mine Cooling, Ventilation Optimization, and Turnkey solutions. https://www.howden.com/en-gb

For support, please contact: This email address is being protected from spambots. You need JavaScript enabled to view it.

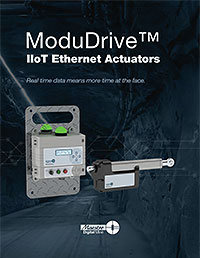

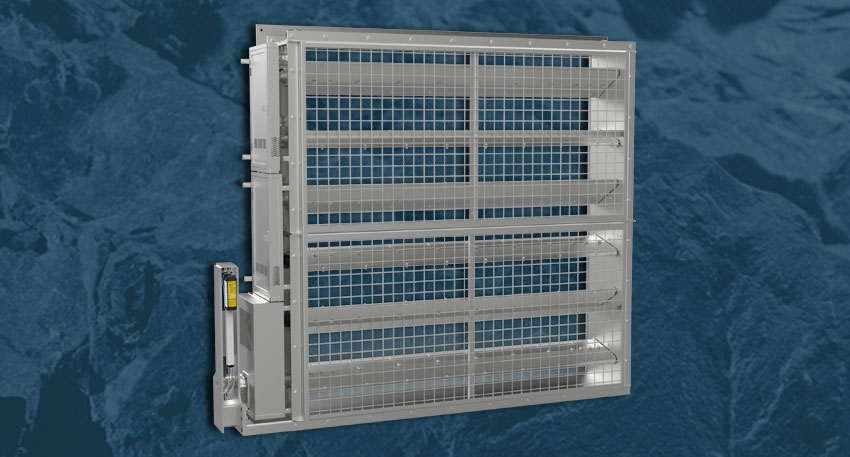

MaestroFlex™ automated regulators are designed to meet the harsh underground mining drill and blast cycles for decades of service. ModuDrive™ digital IIoT actuators provides real-time diagnostics that allows troubleshooting from surface through MaestroLink™ Server.

MaestroFlex™ automated regulators are designed to meet the harsh underground mining drill and blast cycles for decades of service. ModuDrive™ digital IIoT actuators provides real-time diagnostics that allows troubleshooting from surface through MaestroLink™ Server.