Three Signs Your Underground Gas Sensors Need Replaced

The most dangerous gas present underground is not carbon dioxide.

It is not nitrogen dioxide or sulfur dioxide.

The most dangerous gas underground is the one that goes undetected.

Undetected methane accumulation was a critical factor in one of the deadliest mining disasters in modern U.S. history. On April 5, 2010, a methane ignition at the Upper Big Branch Mine in West Virginia escalated into a massive coal dust explosion, killing 29 workers. Subsequent investigations found that hazardous gas conditions were not reliably identified in time by required examinations and monitoring systems.

Later that same year, methane explosions at the Pike River Mine in New Zealand claimed the lives of 29 miners. The Royal Commission of Inquiry concluded that failures in gas monitoring systems, sensor reliability, maintenance, and safety management allowed dangerous conditions to persist undetected.

The lesson from these tragedies, and many others involving toxic gas exposure, is not that gas monitoring systems were absent.

It is that the presence of monitors does not guarantee accurate detection.

Gas detection systems are sophisticated electronic devices, and like all such equipment, their sensors degrade over time. Environmental exposure, contamination, vibration, temperature extremes and normal wear are all factors that gradually affect how sensing elements respond.

When that degradation occurs, it rarely announces itself. From the surface, it appears to be functioning as normal. Devices remain powered, readings continue to display, alarms are still enabled and ready to sound. Underground, however, that façade of normalcy can be misleading. The sensor may still be reporting data, but no longer with the accuracy or responsiveness to reflect real conditions. Decisions continue to be made based on that data, even as its reliability declines.

Apart from regular bump testing, recognizing when sensors are no longer performing as intended is critical. Below are three clear signs that gas sensors should be replaced before degraded performance turns into exposure, injury, or worse.

1. Your readings need a reality check

One of the clearest signs a gas sensor needs to be replaced is when its readings are repeatedly unreliable. For instance, in an area where diesel equipment is frequently operated, your sensors should historically show a predictable rise in measured gases. If, over time, the same equipment produces smaller or slower changes in readings than expected, or worse, fails to detect any gas at all, it means the sensor isn’t doing its job.

2. Calibration becomes a recurring nightmare

Speaking of calibration, another clear sign that a gas sensor may need to be replaced is when calibration stops being a routine task and starts becoming a recurring problem.

In these cases, calibration can still be completed, but the results rarely stick. A sensor may come back into specification at first, only to drift again a week later. When calibration starts failing frequently, your sensor is waving a red flag and telling you its core technology is breaking down and continuing to rely on it is a recipe for risk.

3. It’s seen better days

Mining environments are harsh. Dust, water, vibration and temperature extremes all take their toll, even on the most durable of sensors. Any visible physical damage, from a cracked casing or broken screen to a worn-out button or corroded battery compartment, can compromise the integrity of the sensor itself. If your gas sensor is starting to show its age, it’s time to replace it.

The events at Upper Big Branch Mine and Pike River Mine are reminders that gas monitoring systems can be present while hazardous conditions still go unrecognized. Reliable detection depends on sensors performing as intended, not simply existing within the system.

Ensuring detection remains dependable includes recognizing when sensors have reached the limits of their effective life and replacing them before accuracy declines.

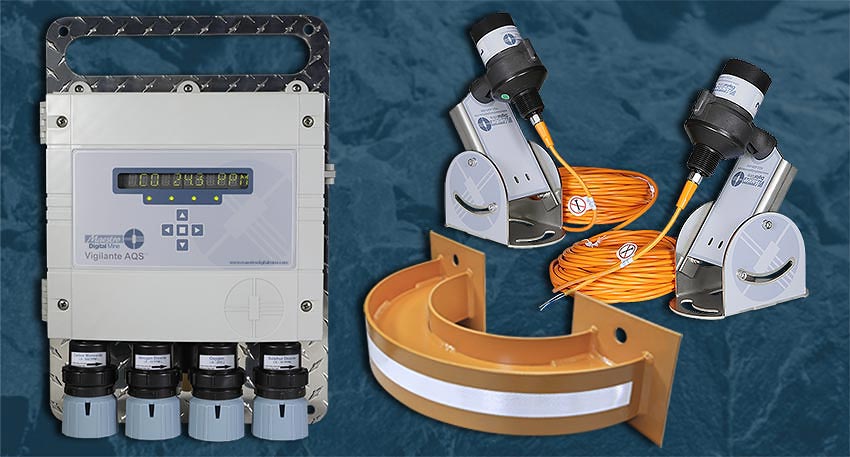

At Maestro Digital Mine, air quality monitoring is designed to be maintained over time, not installed and forgotten. Sensors within Maestro monitoring stations are intended to be tested, serviced, and replaced as operating conditions and performance change underground.

For support with sensor replacement and air quality monitoring, contact sales@maestrodigitalmine.com.