At Maestro Digital Mine, we continue doing business so that we can provide quality service and support to our clients and community members through these unprecedented times.

Our team will continue to provide full support and service to our customers, partners, suppliers and distributors.

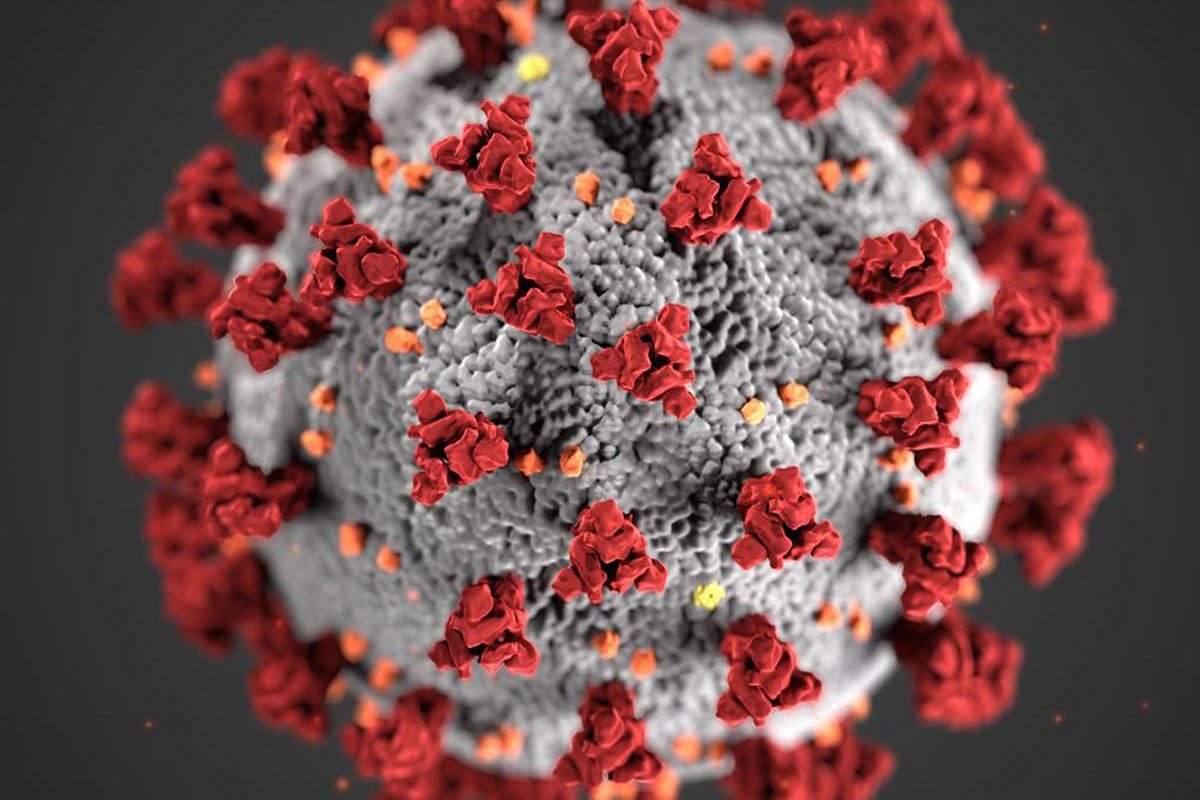

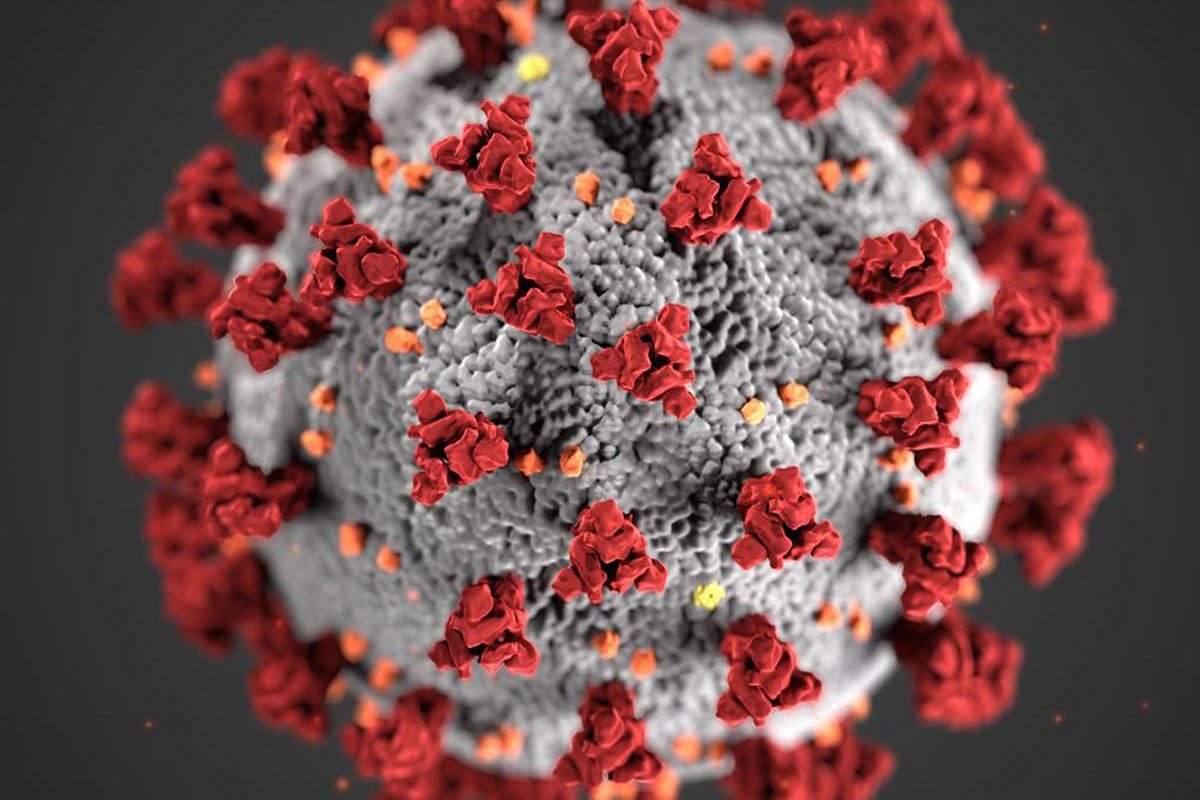

Please review our Covid-19 Protocols for Maestro Digital Mine (PDF)

Maestro Digital Mine deemed an essential service to the mining resource sector and remains focused on the health and safety of our employees.

Maestro continues to provide support to the underground mining sector, keeping miners safe with gas sensors and airflow sensors.

Our team is staying well informed and complying on all recommendations from the Canadian government and health agencies such as the CDC and WHO.

At Maestro Digital Mine, we leave no one stranded.

For customer support services email: This email address is being protected from spambots. You need JavaScript enabled to view it. or dial +1 (705) 805-6918.

Ongoing coverage and updates from by Daniel Gleeson at the International Mining Magazine.

Quebec miners shut down operations following COVID-19 government order...

Maestro Digital Mine one of the recent Ontario-based suppliers to confirm it was “deemed an essential service”. It said it would continue to provide support to the underground mining sector, “keeping miners safe with gas sensors and airflow sensors” during this time.

Read More on this article in International Mining Magazine March 2020 Issue.

As businesses start to navigate through the COVID-19 pandemic, we felt it important to communicate with our valued clients, contacts and friends during this time.

We will continue doing business so that we can support one another and help clients and community members through these unprecedented times.

Maestro Digital Mine is focused on the health and safety of our employees. In order to protect the health and well being of our staff, their families, and our community at large and to reduce the spread of COVID-19, we have provided staff the tools and resources to work remotely. Employees doing essential work at the office and at client sites are following site protocols and to reduce exposure by avoiding unnecessary contact and working from home when possible.

We remain open, with multiple lines of communication activated to ensure business as usual continuity. Our team will continue to provide full support and service to our customers, partners, suppliers and distributors.

- We will remain available for phone calls, emails and online chats and video conferencing as required from 8:00 am to 5:00 pm EST, Monday to Friday.

- Our emergency service will remain available 24/7, always using recommended practices to limit the spread of the virus and following client site protocols.

- We have taken measures to secure and stock our supply of electronic sub-components for a complete year’s worth of manufacturing, so that we will be able to fully support and deliver in both the short and long term.

Maestro is committed to following the advice and guidelines of the Public Health Agency of Canada and the World Health Organization (WHO) and continue to monitor this developing situation. We encourage you to follow the advice of your public health agency and practice social distancing; to learn more about COVID-19 and how to protect yourself, visit the World Health Organization: https://www.who.int/emergencies/diseases/novel-coronavirus-2019

On behalf of our entire team, we thank you for your confidence and as a partner of your company we wish you health and well-being for all and a rapid return to normal.

If you have any concerns, please don’t hesitate to contact us.

Michael Gribbons and David Ballantyne

Co-Founders

Maestro Digital Mine

View PDF version

Despite this, Maestro has gained a reputation for providing ventilation control and environmental monitoring solutions that are ready to cope with the diversities of today’s and tomorrow’s underground mines.

Despite this, Maestro has gained a reputation for providing ventilation control and environmental monitoring solutions that are ready to cope with the diversities of today’s and tomorrow’s underground mines.